تائف

ةديدج ةنودم

Choosing the Right Material and Specifications for RS485 Ethylene Oxide Sensors to Accurately Safeguard Safety

February 06 , 2026In fields such as medical sterilization, industrial production, and warehousing logistics, ethylene oxide (EO) is widely used as a highly effective broad-spectrum sterilizing agent. However, its flammable, explosive, toxic, and hazardous characteristics impose strict requirements for safety monitoring. In recent years, the RS485 ethylene oxide sensor, which integrates the advantages of digital transmission, anti-interference capability, and long-distance monitoring, has become a core component of intelligent gas monitoring systems. Faced with a plethora of products on the market, how can one make an informed choice based on key materials and core specifications? This article provides an in-depth analysis.

I. Enclosure Material: The First Line of Defense for the Sensor

The sensor enclosure is the barrier that protects against environmental erosion and ensures the stable operation of internal components. The choice of material directly determines the device's adaptability in different scenarios.

Stainless Steel Enclosure (Preferably 316L): The "armor" for industrial environments. Its exceptional corrosion resistance allows it to easily withstand harsh conditions such as high humidity and chemical vapors (e.g., disinfectant residues). It is particularly suitable for medical device sterilization workshops, chemical plant peripheries, and similar locations. Although the cost is higher, its long service life and unparalleled reliability make it perfectly suited for demanding on-site environments.

Aluminum Alloy Enclosure (Surface Anodized): Strikes a good balance between weight, cost, and protection. Anodized aluminum alloy offers decent corrosion resistance and good heat dissipation. Paired with a lightweight design of 120g, it is suitable for general warehouses, logistics centers, and other indoor scenarios with relatively dry environments and minimal corrosive gases.

Engineering Plastic Enclosure (e.g., ABS, Polycarbonate): The greatest advantages are lightweight, insulation, and cost-effectiveness. Suitable for fixed monitoring points where explosion-proof rating requirements are relatively lenient and the environment is stable and clean. However, there is a risk of material degradation with long-term sun exposure or contact with specific chemicals, so it should be avoided in environments with high concentrations of corrosive gases.

Selection Advice: Prioritize based on the corrosiveness of the installation environment and budget. Stainless steel is essential for highly corrosive environments. For generally dry indoor environments, consider the more cost-effective aluminum alloy or high-quality engineering plastics. Simultaneously, avoid placing the device in environments with humidity consistently above 95% for extended periods to prevent damage to the enclosure and internal components.

II. Sensing Element and Internal Materials: The Core Determining Performance

Inside the enclosure, the materials of the sensing element that directly contacts and detects ethylene oxide, along with related components, are the core guarantees for the sensor's sensitivity, response speed, and service life.

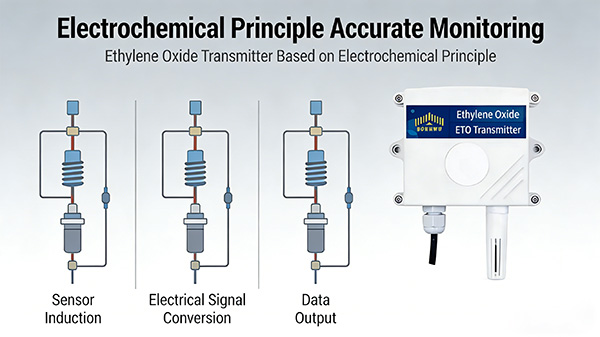

Electrochemical Sensing Principle: This is the mainstream core technology for current ethylene oxide detection, utilizing the synergistic action of catalytic electrodes and electrolyte to achieve gas detection. High-quality products typically use precious metals like platinum or gold as catalytic electrodes, offering sensitive reactions and strong stability. Combined with optimized electrolyte formulations and encapsulation processes, they can significantly enhance anti-interference capabilities, ensuring accurate detection even in complex environments.

Key Auxiliary Materials: The materials of components such as gas permeable membranes and filters are equally critical. For example, hydrophobic PTFE (Polytetrafluoroethylene) membranes can effectively block moisture and dust from entering the sensing chamber, preventing component "poisoning" and failure, while allowing target gases to pass through quickly, providing solid support for the 1-second data update speed.

Lifespan Assurance: The design service life of such sensors is typically around 2 years. In actual use, attention should be paid to the stability of the core materials. Prioritize products labeled with features like "resistant to cross-interference from formaldehyde, etc." to avoid shortened lifespan or decreased detection accuracy due to poor auxiliary materials.

Selection Advice: Pay attention to the brand's accumulation in core electrochemical technology. Prioritize products that clearly indicate strong anti-interference capability and a service life close to the design standard. For areas with complex environments and the presence of multiple disinfectants, high-selectivity sensors are essential to effectively avoid detection errors caused by cross-interference.

III. Key Specification Parameters: The Precise Gauge for Matching Requirements

After selecting the right materials, it is necessary to perfectly align the sensor with specific requirements through core specification parameters, ensuring efficient and accurate monitoring.

Range and Accuracy: The mainstream standard range is 0-100ppm with a resolution of 0.1ppm, meeting the fine detection needs of most scenarios like medical sterilization environment leakage monitoring. Temperature and humidity detection accuracy can reach ±0.3°C, providing environmental compensation for ethylene oxide concentration detection and further ensuring data accuracy. For scenarios like industrial process monitoring that require larger measurement ranges, custom models can be inquired about separately.

Response and Update Speed: The data update time requires only 1 second, coupled with a fast-response design (T90 is typically within 30 seconds), enabling real-time monitoring and rapid alerts. This is especially suitable for scenarios with high timeliness requirements, such as post-sterilization residual monitoring in medical settings.

Environmental Adaptability: The operating temperature range is -20°C to 50°C, and the humidity range is 15% to 90% RH (non-condensing). Selection must confirm compatibility with the installation environment. After long-term storage, the device requires a 24-hour aging period; initial use requires a 48-hour aging period. This is a key prerequisite for ensuring subsequent detection accuracy.

Protection and Explosion-Proof Rating: The waterproof enclosure design allows adaptation to some humid environments. If used in potentially explosive atmospheres, it is necessary to additionally confirm whether the product possesses the corresponding explosion-proof certification to avoid safety risks.

RS485 Communication Details: Supports the ModBus RTU protocol, using a communication standard of 8 data bits, 1 stop bit, and no parity bit. The baud rate can be selected between 2400 and 115200 bit/s (default 9600 bit/s), with a maximum communication distance of up to 2000 meters. It supports multiple devices on a single bus (attention must be paid to avoiding address conflicts). During selection, confirm compatibility of communication parameters with the existing system in advance to ensure smooth integration.

Selection Advice: Prioritize the standard 0-100ppm range for selection; refer to accuracy within ±3% FS as a quality industry standard. Baseline response time and data update speed should be at the 1-second level; faster is better for improving alert timeliness. Environmental parameters must strictly match the usage scenario to avoid operation beyond limits. Communication details must be confirmed in advance with the system integrator to ensure protocol, baud rate, and other parameters are consistent.

Summary: Precise Selection Builds a Reliable Safety Barrier

Choosing the right RS485 ethylene oxide sensor is a systematic weighing process: First, assess the corrosiveness, temperature, humidity, and explosion risks of the application environment to determine the enclosure material and protection level, preventing device failure due to environmental factors. Second, focus on core performance by selecting products based on high-quality electrochemical materials, clearly labeled with anti-interference capability and lifespan specifications, ensuring precise and stable detection data. Finally, quantify specific requirements by aligning specifications such as range, accuracy, and communication parameters, ensuring the sensor's performance fits the monitoring objectives perfectly.

In matters concerning life and production safety, a thorough investigation into sensor materials and specifications is by no means an overreaction. It is about using the precision and rigor of technology to construct an invisible yet crucial reliable barrier, safeguarding the safe operation across various fields.https://www.zonewuiot.com/gas-sensors_c11